Material: Frame and vent members extruded 6063 temper T5 aluminum. Normal thickness of .062" commercial tolerance. Weatherstripping shall be elastometric vinyl and shall be sealed in self-locking grooves extruded integrally in frame and vent members.

Any weatherstrip section shall be replaceable without disassembly of frame or vent.

Construction: Frame and vent corners shall be mortise and neatly fitted together to form a weather tight joint. Corner joints are to be firmly fastened together.

When window is in closed position, there shall be full weathering contact around the perimeter of the vents. Sill of each vent shall have a flange extending overhead of vents underneath.

Drip caps shall be integral and extend beyond full width of vents. Hardware shall be so designed as to permit easy removal, as an assembly, before or after erection.

The design and construction of the window shall permit vents to be readily installed or removed from the interior of the building with the sue of tools.

Window shall open to such a position as to allow cleaning of all exterior surface from building interior.

Operation: Opening and closing of vents shall be accomplished by a heavy duty off-set gear-type operator for activating a torque bar, which in turn transmits power in equal amounts through the hardware to the vent sides.

Glazing: Vents shall be glazed at the factory with snap-in aluminum glazing bead. Windows shall be suitable for field glazing in necessary.

Glass options shall be clear, tinted, solar reflective.

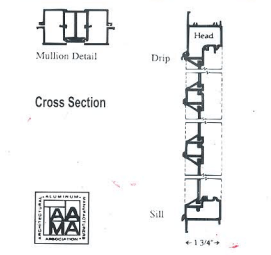

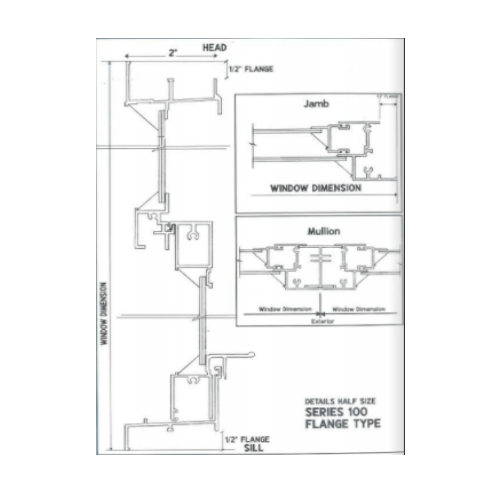

General: Aluminum single-hung windows as manufactured by Bahamas Aluminum Manufacturing Co. Ltd. to meet or exceed the American Architectural Manufacturers Association (AAMA) specifications.

Materials: All frame and sash members shall be extruded 6063-T5 architectural aluminum alloy. Frame members to be 2" deep with a wall thickness of .062". Sash members to be 1" deep with a wall thickness of .062".

Construction: Window shall be coped at the corners and mechanically assembled with joints properly sealed.

Hardware: Sash operates on concealed block and tackle balances. Sash may be removed for cleaning purposes. Locking hardware shall be a cast aluminium latch located at the meeting rail.

Watherstripping: Double wool pile located inside and outside at vertical members of the operable sash. Single wool pile located at the meeting rail and and elastometric vinyl located at he sill and bottom rail.

Finish: Aluminum to be factory applied acrylic, baked-on white finish.

Glazing: Factory glazed with double-strength (1/8" thick) glass retained by aluminum glazing bead.

Screens: Rolled formed aluminum frames with 18 x16 fiberglass mesh.

At first glance, a pane of laminated glass looks much like any other. Scrutiny reveals its functional design and protective capabilities. Laminated glass performs. It is durable. It offers proven features that shield homeowners from interference by the outside world. Yet laminated glass is flexible enough to meet stringent architectural design requirements. Using heat and pressure, a tough layer of polyvinyl butyral, or PVB, is bonded between two panes of annealed, tempered, or heat-strengthened glass. Depending upon the gauge of the glass, this technology helps protect homes and homeowners from intrusion, injury, and the sun's harmful rays.

Bahamas Aluminum Manufacturing windows with laminated glass range from two to four times stronger than traditional windows. And, if the window should break, fragments tend to adhere to the PVB inter layer, reducing the number of flying shards and reducing the risk of injury from broken glass. PVB inter layers are available in .030" gauge providing added safety protection, effectively reducing UV and sound penetration into the home.